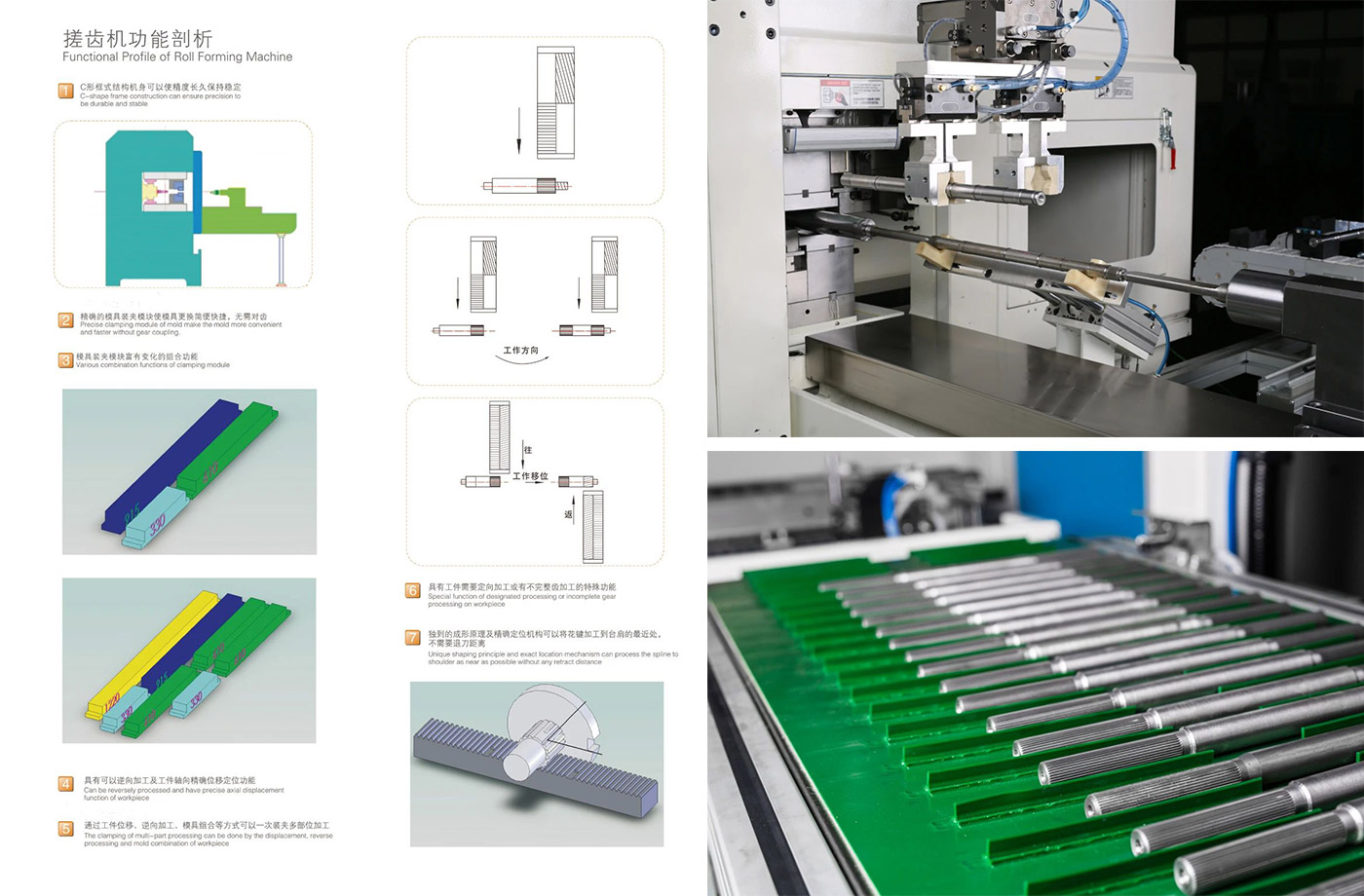

Driver Shaft | Intelligent rolling & groove cutting case

The Driver Shaft, also known as CVJ,CV joint,constant Velocity joint, is the Shaft connecting the differential with the drive wheel.Driver Shaft is the shaft that transmits torque between the gearbox reducer and the driving wheel (mostly in the solid befo

Crafting process

| Workpiece name | Driver Shaft |

| Machine type | LC800EA |

| Manufacturing procedure | Rolling&groove cutting |

The Driver Shaft, also known as CVJ,CV joint,constant Velocity joint, is the Shaft connecting the differential with the drive wheel.Driver Shaft is the shaft that transmits torque between the gearbox reducer and the driving wheel (mostly in the solid before, but because of the hollow shaft rotational imbalance control easier, therefore, a lot of cars with hollow shaft), its inside and outside on one side of a universal JOINT (U/JOINT) respectively by the spline on the universal JOINT and gear reducer and wheel hub bearing inner ring connection.

power between the differential and the drive wheel.The shaft of the common non-break type drive shaft can be divided into three types according to the different supporting forms of the outer end: full floating type, 3/4 floating type and half floating type.

In LECN's ten years of operation, has been adhering to the in minority areas to provide clients with the most professional service and the most comprehensive product selection, depth of spline cold forming technology has been LECN's research and development of key areas, in more than a decade to more than 300 users at home and abroad to provide the rolling machine equipment, nearly 1000 sets throughout the automobile motorcycle, engine, gearbox transmission shaft, the direction of machine, starter motor, brake, spring torsion bar, textile roller, washing machines, motor, elevator and reducer, and many other fields.

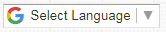

Performance feature:

◎ Wear resistant castings made of special materials and the body of C-type closed frame;

◎ Abundant mold combination, can reverse rolling to save mold;

◎ One time clamping, can reciprocate multi - stage rolling;

◎ Intelligent guide lubrication inspection function, workpiece forming large flow cooling;

◎ Reasonable structural design, pleasant control height, saving floor space;

◎ It can be equipped with truss or joint robot to support automatic line connection.

1、Rolling machine of LECN

LC800EA/LC1000EA/LC1500EA

◎ Double servo motor full closed loop synchronous drive to achieve low noise precise forming process;

◎ Intelligent full servo front and rear top technology can effectively solve the security identification of clamping.

2、Function description and structure characteristics of CNC groove cutting machine

(1) HL203 CNC groove cutting machine tool is suitable for groove cutting of cylinder, cone and various shaped rotary surfaces.

(2) High stiffness and low center of gravity frame.

(3) Mobile spindle, hydraulic drive center.

(4) Adopt high rigidity spindle bearing.

(5) The X and Z axes are supported by precise screw bearings to ensure the conveying stability and accuracy after thermal expansion.

(6) Equipped with precision linear guide rail, can achieve rapid movement of 16m/min, reduce the non-cutting time, improve production efficiency.

(7) Servo motors are directly connected through precision couplings, which can optimize the variation of conveying accuracy caused by load.

(8) Equipped with high-performance CNC system full servo drive.

(9) Simple and beautiful appearance and effective protection design.

(10) Functional modules and configurations that can be personalized.